Establishing and maintaining safe navigation is an unalterable mission in the marine transporatation business. "K" LINE Group states in its corporate philosophy and vision " to provide safe and optimal services " and to contribute to society through safe vessel operations. At the same time, this also means contributing to the reduction of environmental impact on the oceans and the atmosphere, and efforts to preserve biodiversity, especially in the oceans, is an important theme for our business adtivities. We will continue to strive th reduce the environmental impact of our vessel operations on the oceans and atmosphere by promoting initiatives such as to eliminate oil pollution incidents, ballast water management, SOx and NOx emission reduction measures, and reducing the impact of vessel operations on marine mammals.

In January 2025, Kawasaki Kisen Kaisha, Ltd. (“K” LINE) has enriched its information disclosure with a focus on governance, strategy, risk and impact management and metrics and targets in accordance with the Taskforce on Nature-related Financial Disclosures (TNFD) framework version 1.0 (official version), published by the TNFD in September 2023.

As a part of its disclosure of information based on the TNFD framework, “K” LINE introduced the LEAP approach proposed by the TNFD for the evaluation of environmental risk and the nature-related impact of its business and it comprehensively assessed risks and opportunities in October 2023. In addition, “K” LINE joined the TNFD Forum in November 2023. In March 2024, “K” LINE registered as a TNFD Adopter, an organization swiftly adopting the disclosure recommendations published by TNFD in September 2023 and endeavored to continuously enrich the information it discloses.

The Group’s businesses are dependent on natural capital, mainly from the ocean, and it considers its efforts to address not only climate change issues but also biodiversity conservation, especially in the ocean, to be one of the most important themes in its business activities. To more strictly manage risks and opportunities based on a comprehensive understanding of climate change and natural resources, “K” LINE will continue to enrich its assessment, analysis, and disclosure of information with a view toward the establishment of a sustainable future.

Safety in navigation and cargo operations is an immutable mission in a shipping business. The “K” LINE Group contributes to society through safety in cargo and navigation operations by providing reliable and excellent services, as stated in our corporate principle and vision. At the same time, we will contribute to reducing our impact on the sea and air, continue promoting efforts to reduce oil spill accidents to zero, and reduce the environmental impact from vessel operations.

・Strengthen safety in navigation(use the optimal navigation suppor system and develop automatic ship navigation for vessel steering and engine plant operation)

・Enhance ship resilience, such as seaworthness, and maneuverability

・Strengthen all other safety measures, including safety training for staff

• Continue measures to manage ballast water, reduce emissions of sulfur oxide (SOx) and nitrogen oxide (NOx), and install equipment to comply with regulations

• Reduce the impact of shipping operations on marine mammals

• Increase staff environmental awareness

Kawasaki Integrated Maritime Solutions, which was rolled out across our fleet in March 2016, continues to focus on developing engine plant operation support and failure prediction and diagnosis. Together, these enhance our safety in navigation and environmental protection measures.

The “K” LINE Group Environmental Award recognizes Group officers and employees who take action to protect the environment and biodiversity and provide a significant contribution to the sustainability of our business operations.

We provide training programs for our Group employees on our environmental management system (EMS) with the aim of maintaining and raising environmental awareness, including improving energy efficiency, waste disposal and pollution prevention, and efficient water use. (Attendance rate: 80%)

Our internal portal site contains a variety of information, including the “K” LINE Group Environmental Policy, the Environmental Management Manual and a list of environmental managers as well as environmental activity reports and materials used in environmental seminars. We strive to make the site and its information easy to use and understand so that each and every “K” LINE employee can increase their knowledge and awareness of the environmental management system and environmental issues.

The Environment Management Group holds “environment seminar” and “environmental e-learning” each year for employees of “K” LINE and some of our Group companies under the initiative of the Environment Management Group of “K” LINE.

- 拡大

- Environmental training

Under the direction of ““K” LINE Environmental Vision 2050,” as our long-term environmental management vision toward 2050, we founded “K” LINE Group Environmental Award in order to assist group-wide efforts for environmental conservation and biological diversity to assure sustainable operations for all executives and employees of both “K” LINE and the entire “K” LINE Group.

- 拡大

- Award winners

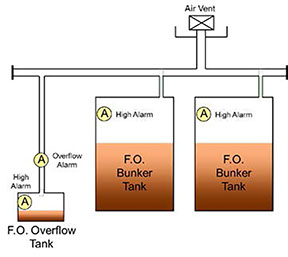

When bunkering, if fuel is supplied to the fuel tank of our ship beyond capacity, there is a possibility of fuel flowing out of the ship through the air-vent of the fuel tank.

In order to prevent this situation, we have installed an overflow pipe in the overflow Tank in order that fuel oil spilt out of the fuel tank flows into the overflow tank, and furthermore, a flow detection sensor in the pipe or a high-level alarm sensor in the tank in order to detect overflow immediately.

- 拡大

- Overflow Pipes and Overflow Tanks

We apply an air seal for the stern tube of our ships. An air seal is a device that continuously sends compressed air into the space in the section where the propeller shaft penetrates from the inside to the outside of the ship. This creates a sealed area inside the stern tube, which separates lubricating oil and seawater.

- 拡大

- Air Seal for the Stern Tube

We have introduced to our new ships electrically driven deck equipment, such as a mooring winch (*1) and a ramp way (*2) that used to be hydraulic powered equipment. This has eliminated the risk of leakage of hydraulic oil used for hydraulic driving.

*1 mooring winch: a device for winding up a rope or a wire to moor a ship.

*2 ramp way: a sloping path to be stretched to a quay when cars are loaded onto a car carrier ship and when they are landed. It is stored during a voyage.

- 拡大

- Electric Mooring Winches and Mooring Lines (bow)

It is a device for cooling the engine and lubricating oil by indirectly exchanging heat with seawater via dedicated freshwater. Use of this system prevents leakages or overboard spills of lubricating oil due to trouble in the cooling system, because thermal exchange is not directly made between lubricating oil and seawater in this system.

- 拡大

- Indirect Cooling System

When sea creatures attach to the hull, the resistance of the hull increases, and fuel consumption increases. This results in an increase in CO_{2} emission.

When those attached sea creatures are brought into other sea areas during voyage, it will affect the ecosystem (of those areas).

Our company encourages adoption of low friction paint for new ships to reduce fuel consumption and prevent attaching of sea creatures, and are also trying to reduce CO_{2} emissions and maintain the biological diversity.

We also encourage use of low friction paint, as well as existing paint, for ships that are already in service.

A ship being coated with silicone paint

(red color) at the Dry dock

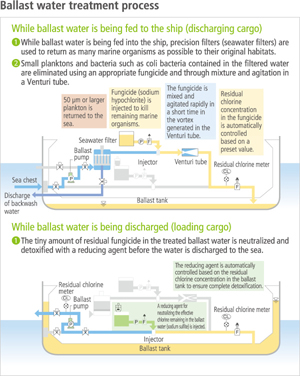

Vessels store seawater (ballast water) to keep the hull stable at sea.

In 2017, the International Maritime Organization (IMO) has entered into force the "International Convention for the Control and Management of Ships’ Ballast Water and Sediments " because the discharge of ballast water from vessels can affect marine ecosystems.

Specifically, it requires the installation of a treatment system (BWMS: Ballast Water Management System) for sterilizing ballast water.

We will continue to operate vessels that are cleared of regulations and strive to protect biodiversity so that marine life and ecosystems as they originally are.

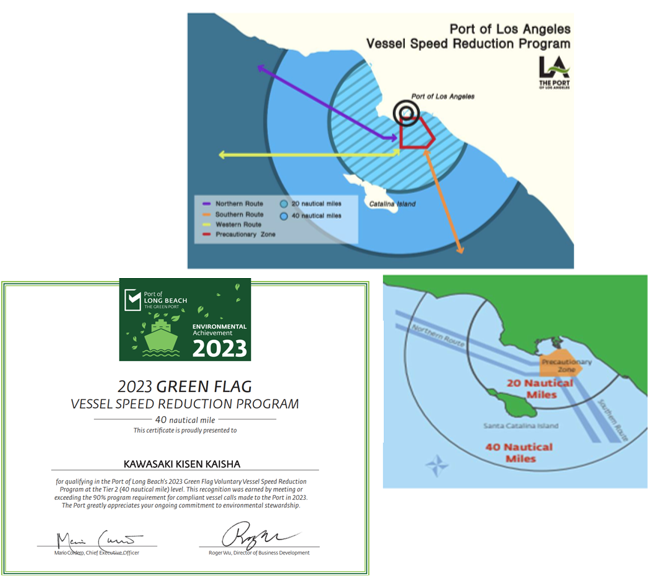

Kawasaki Kisen Kaisha, Ltd. (“K” LINE) is honored to have received recognition from the port authorities of Long Beach and Los Angeles, both in the United States, for recording high level of compliance throughout 2023 with voluntary speed reduction by “K” LINE’s car carriers and dry bulk carriers in the two ports’ respective programs in order to reduce coastal air pollution by slowing ships within the designated water. Ships participating in the program are asked to comply with speed limit of 12 knots within 40 miles (about 74 kilometers) from the coast of each port in order to reduce emissions of exhaust gases containing nitrogen oxide (NO_{x}), sulfur oxide (SO_{x}), particulate matter (PM) as well as CO_{2} that cause (global) warming from ships. We have long participated in the program aggressively, and as a result of this year’s achievement, “K” LINE has been honored to receive this award from the Port of Long Beach for 19th consecutive years since 2005 and from the Port of Los Angeles for 16th consecutive years since 2008 when their awards were commenced, respectively.

We voluntarily reduce the speed of our car carriers to 12 knots or less when navigating in Ise Bay and Mikawa Bay as our own effort. This enables us to reduce the impact of ship navigation on the surrounding atmospheric environment, both on land and at sea. We also control emission of PM (including soot) while ships are in harbor by removing soot from the boiler before entering the ports. After entering the ports, we assure that the load on the electricity generator is appropriate to maintain a good combustion state.

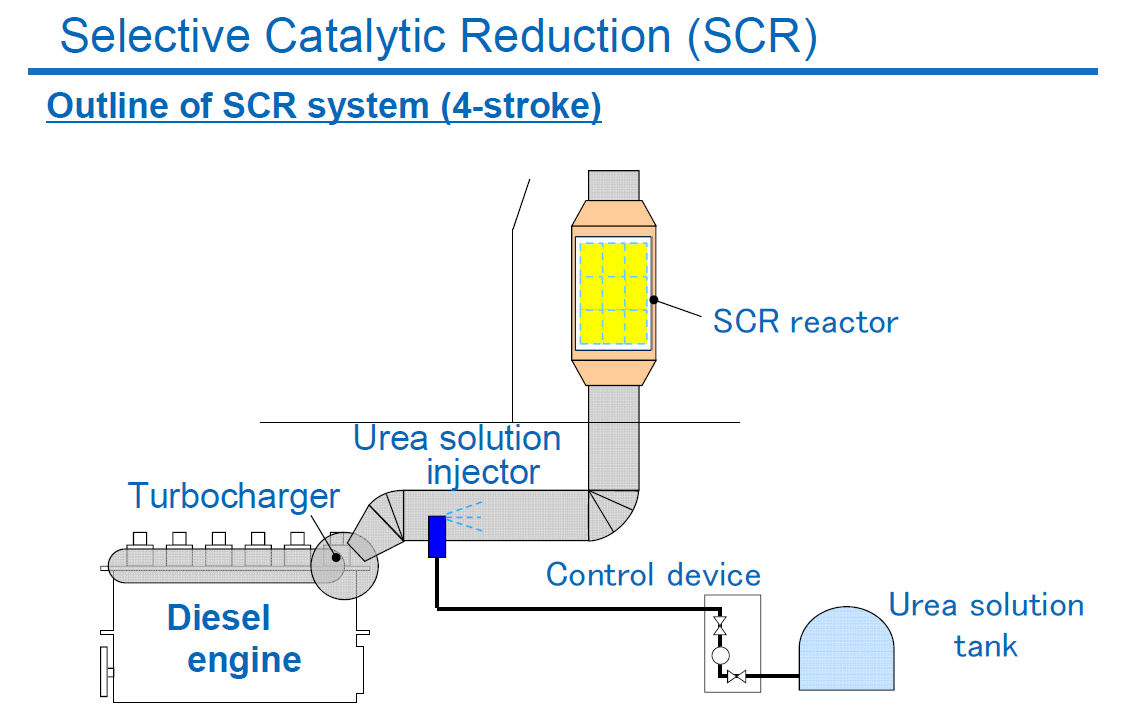

Movement to control NO_{x}(Nitrogen Oxide) discharged from ships is becoming active worldwide. Therefore, IMO (International Maritime Organization) is going to tighten the regulations significantly for new ships in or after 2016 (Tier III regulations).

“K” LINE installed a selective reduction catalyst device (SCR device) adapted to the NO_{x} Tier III regulations to diesel engines for power generators of large containerships that went into service in March 2013 in collaboration with Japan Marine United Corporation and DAIHATSU DIESEL MFG. CO., LTD, conducted an assessment for about a year and a half, and confirmed that the device worked alright on actual ships.

SCR is a technology of binding ammonia (NH_{3}) and NO_{x}, the gases hydrolyzed by heat of the exhaust gas, by spraying urea water used as reduction agent to thereby convert the gases to nitrogen gas (N_{2}) and water (H_{2}O).

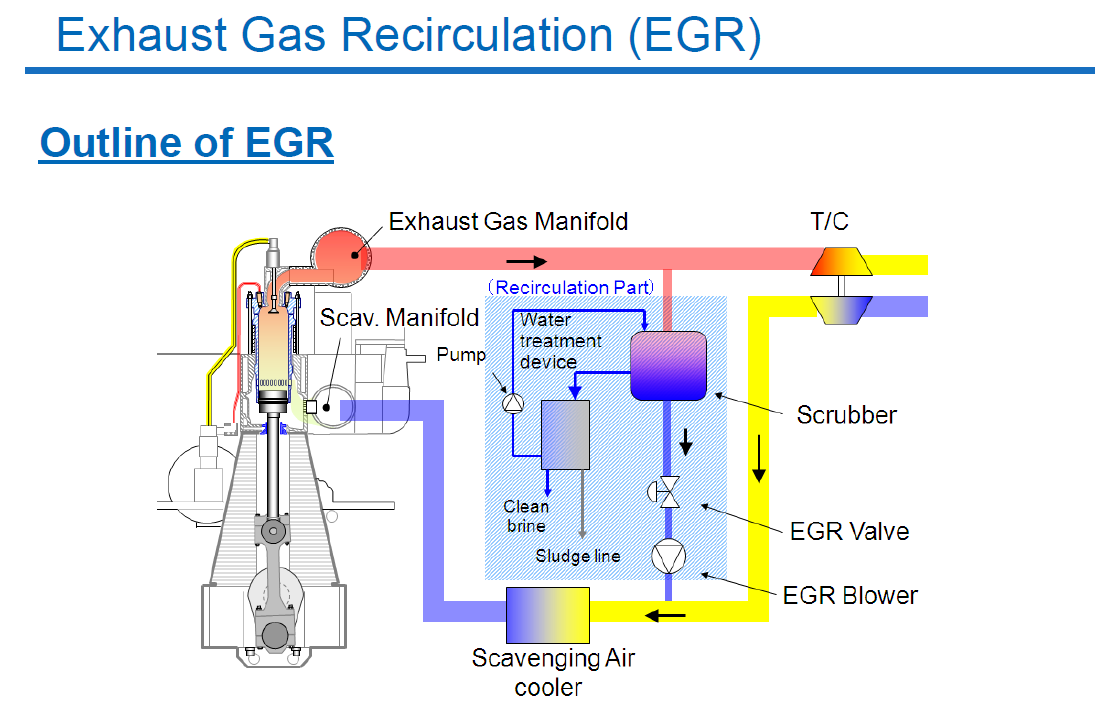

“K” LINE is going to implement operational testing of the exhaust gas recirculation device (EGR device) adapted to the NO_{x} Tier III regulations in collaboration with Japan Marine United Corporation and Kawasaki Heavy Industries Ltd. as well.

EGR is a technology of reducing oxygen concentration at the time of combustion by sending a part of the exhaust gas again after purifying it and lowering combustion temperature to thereby reduce NO_{x}.

We will install the EGR device on the DRIVE GREENHIGHWAY which was completed in February, 2016, and are conducting experiments on actual ships for about two years and from now on.

We are not merely clearing the regulations, but also striving for green hull maintenance with no air pollution, and we are working to develop new technology and put it into practice in collaboration with marine engine manufacturers and shipyards.

Water emulsion fuel and its properties

Water emulsion fuel is a mixture of fuel oil and water that has been agitated to disperse minute water particles within the fuel oil. Water emulsion fuel for diesel engines has been found to result in an approximately 20% reduction of nitrogen oxide (NO_{X}) contained in the exhaust gas. We are undertaking a verification test of equipment for using water emulsion fuel by installing it in ships operated by the “K” LINE Group.

Combustion reaction of water emulsion fuel

Combustion reaction of the water emulsion fuel is illustrated below.

- The water particle is contained in an oil particle.

- When the water emulsion fuel is injected into the engine, the water evaporates before the oil particle is ignited.

- Evaporation of the water causes the fuel particle to disperse into even smaller particles.

- The extremely small particles of fuel are highly combustible, so the probability of perfect combustion increases.

- Combustion efficiency is improved, resulting in cleaner exhaust gas.