Climate change is expected to expose humankind to major physical risks, such as serious natural disasters.

In June 2020, we reviewed our “K” LINE Environmental Vision 2050, and based on the results of the scenario analysis proposed by the Task Force on Climate-related Financial Disclosures (TCFD), identified issues to be addressed and revised some targets.

Furthermore, in November 2021, we recognized global climate change countermeasures as an issue that must be strengthened by the entire international community, and we therefore set a higher challenge of net-zero GHG emissions by 2050. In addition, as a long-term vision in our medium-term management plan announced in May 2022, we are committed to smoothly switching to other forms of energy for our company and society. We will promote the realization to a low-carbon and carbon-free society.

In September 2024, to reflect the ever-changing latest circumstances, we have reviewed our scenario analysis recomended by TCFD and conducted trial calculations of the financial impact of climate change risks and oppotunities in the four areas - governance, strategy, risk management, and metrics and targets - to expand the content of our disclosure.

-

TCFD-Based Information Disclosure

(1,303KB)

TCFD-Based Information Disclosure

(1,303KB)

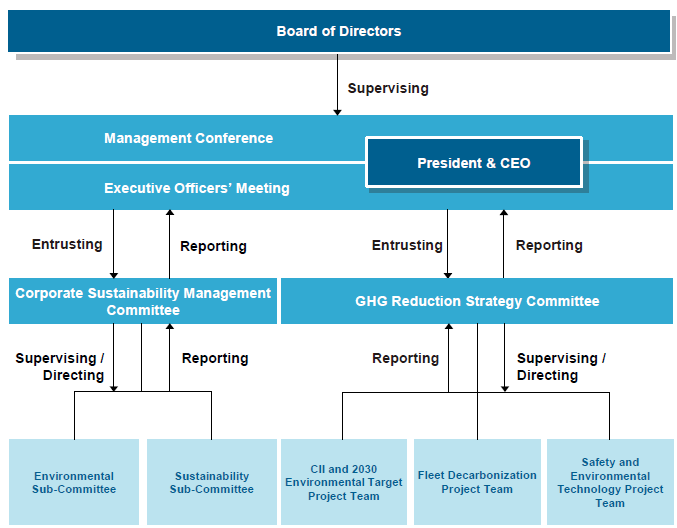

In April 2021, the “K” LINE Group restructured the existing organization and reformed the promotion system for sustainability to ensure it is a key management objective. The Corporate Sustainability Management Committee, chaired by the president & CEO, meets approximately once every two months and works to enhance corporate value by reviewing and formulating a promotion system for the “K” LINE Group’s sustainability management. Another function of the commitee is to indentify climate-related risks and oppotunities and monitor the progress of responses to them.

Additionally, in October 2021, we established the GHG Reduction Strategy Committee by integrating the Alternative Fuel Project Committee, which is in charge of accelerating initiatives for conventional vessels fueled by liquified natural gas (LNG) and the LNG fuel supply business and examining next-generation fuel and new technologies, with the Environment/Technology Committee, which formulates measures for compliance with environmental regulations, including technical aspects. Each of these two committees, the Corporate Sustainability Management Committee and the GHG Reduction Strategy Committee, functions as a forum for strategic discussions.

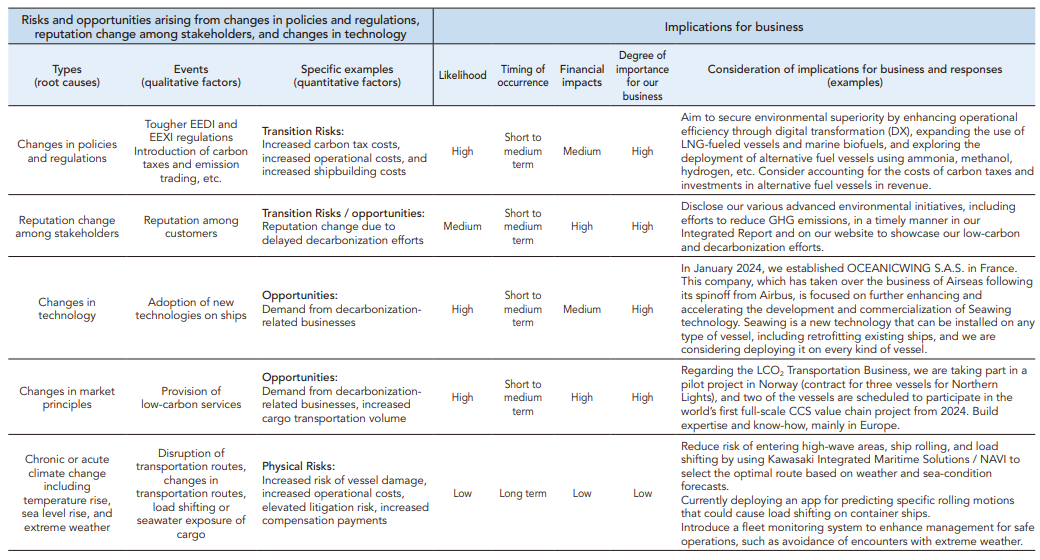

Through internal surveys and interviews wtih relevant departments, we organized the likelihood, timing, and financial impact of climate change-related risks and opportunities, and analyzed their importance to our business. We then summarized our considerations and couneremeasures for the the iimpacts of each risk and opportunity on our business.

※Transition Risks(Policies and regulations, Reputation, Technology, Market principles), Phisical Risks(Chronic or acute)

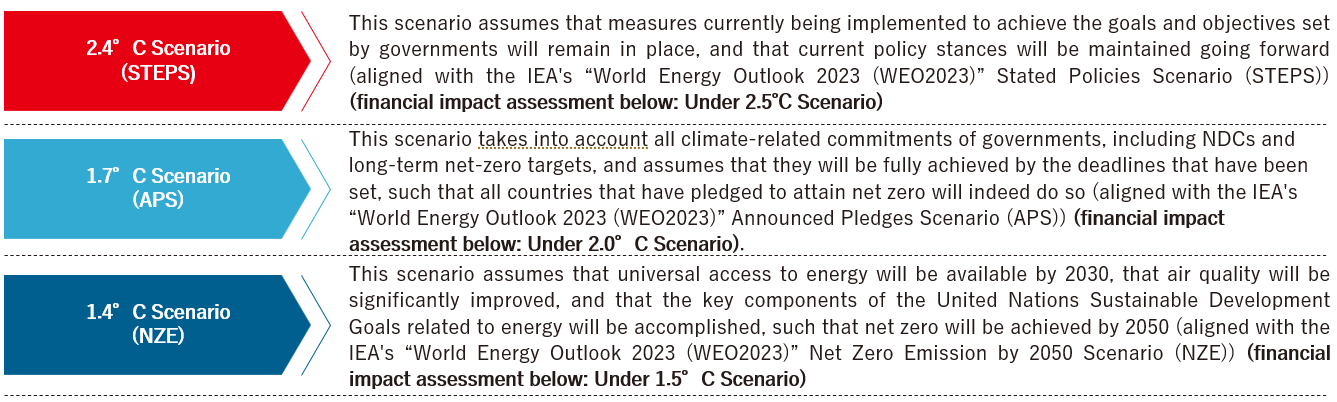

Assumptions for scenario analysis

To assess the sustainability and resilience of our management strategy with respect to the long-term and uncertain issue of climate change, we consider three scenarious:2.4℃ Scenario, 1.7℃ Sceario, and 1.4℃ Scenario. We assess the quantitative financial impacts of risks and oppotunities stemming from climate change in the event that they should actually materialize and consider responsed to them. Additionally, for physical risks, we analyze them under a scenario with an even higher temperature rise than 2.4℃(3.0 ℃ more, equivalent to RCP8.0)

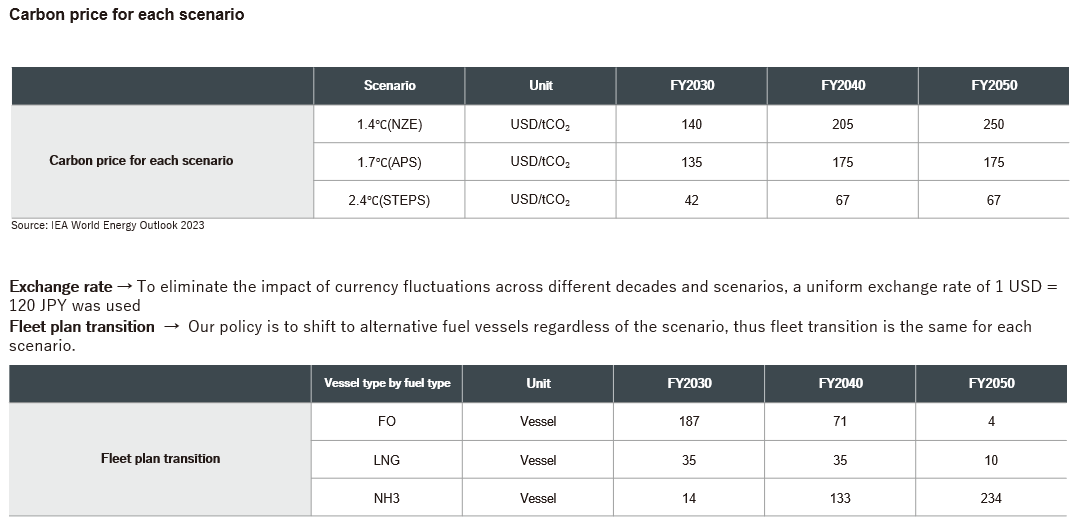

Assumptions/conditions for financial impact calculation

Financial impact calculations are based on the IEA's “World Energy Outlook 2023(WEO2023)”, and where data was inadequate, assumptions have been made with reference to data from external informaion providers.

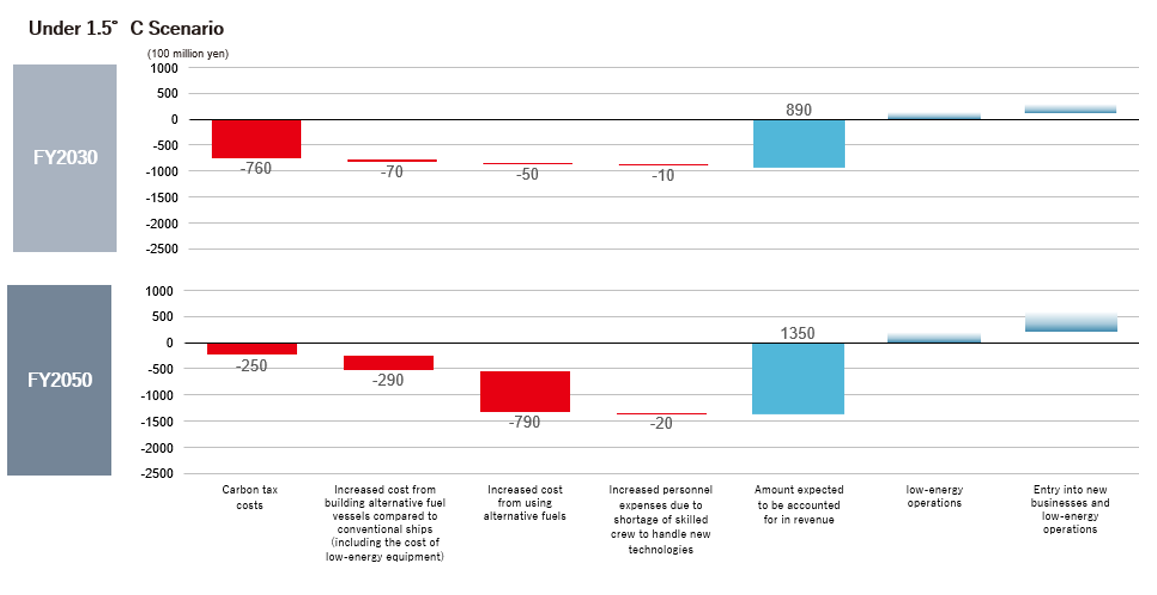

Summary of Results of Financial Impact Assessment for Each Scenario

The results of our estimation of financial impacts reiterated to us that regardless of the temperature scenario, if no action is taken to reduce and eliminate carbon use, nagative impacts on our company will continously occur over the long term. They also led us to recognize the quantitative impact of increased costs associated with low-carbon and decarbonization measures that we will incur under every scenario, and we realized that if we are to continue to develop the company's business and contribute to making people's lives more comfortable, we will need to get society as a whole to bear the increased costs of low-carbon and decarbonization measures that cannot be covered through in-house efforts alone by accounting for them in revenue.

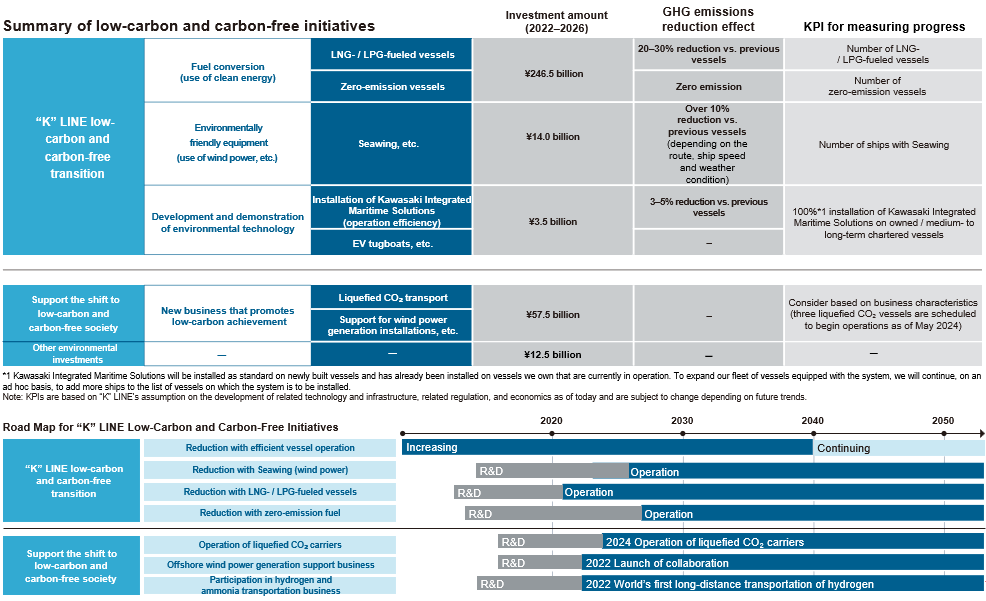

In order to meet the needs for low-carbon and decarbonization and establish a competitive advantage, we will invest a total of 380 billion yen by 2026 to promote reduction measures aimed at our own low-carbon and decarbonized business of society through fuel conversion, introduction of new technologies such as Seawing, and transportaion of liquefied CO₂.

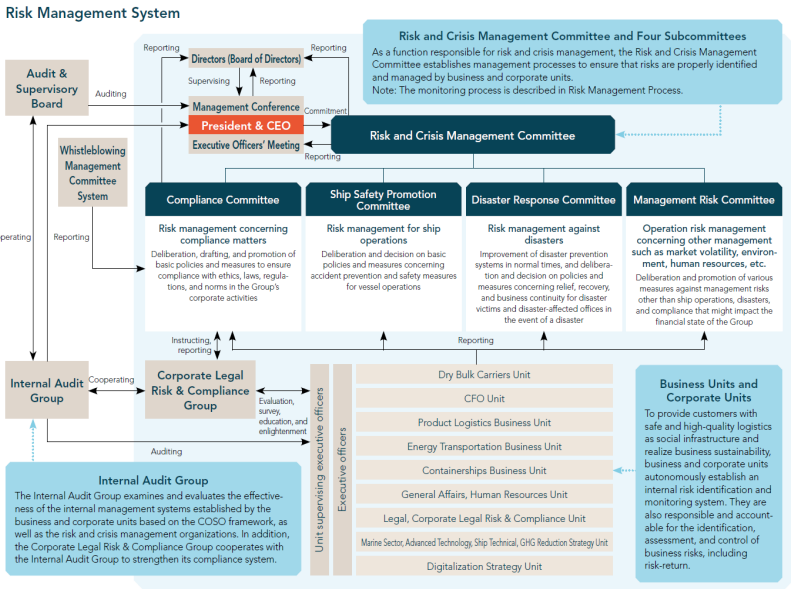

We recognize the impact of external changes and the various risks our operations are exposed to, and we have established a risk management system that will enavle us to fulfill our corporate social responsibilities even when risks materialize.

We classify major risks into four categories: risks associated with ship operations, disaster risks, compliance-related risks, and other business-related risks, and we set up committees to address the risks in each category.

• Additionally, we have established a Crisis Management Committee as an organization that brings together these four committees and oversees and promotes overall risk management.

• The president serves as the chair of all these committees, with meetings held quarterly even during normal times to strengthen risk management.

• The four committees for major risks provide training for risk management at regular intervals and on an ongoing basis. For example, we build up readiness by organizing largescale accident drills and having personnel participate in risk management workshops with other companies. Each year, November is designated as Compliance Month, during which the importance of compliance is thoroughly communicated.

• The Group is acutely aware of the importance of sustainability as essential infrastructure that supports people's lives and the economy. To address risks and leverage opportunities related to environmental conservation and climate change, we conduct scenario analysis on climate change and have formulated the “K” LINE Environmental Vision 2050.

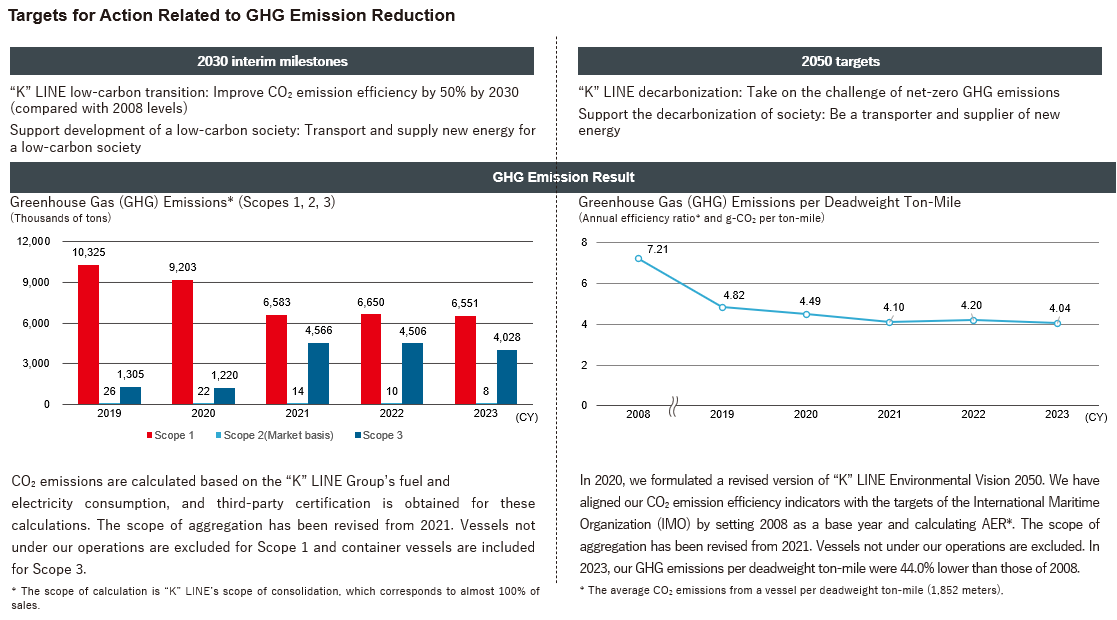

As we move closer to 2030, we will be steadily executing an action plan to achieve the medium-term milestone goals set forth in the “K” Line Environmental Vision 2050. And our new goal for 2050 is to achive net-zero GHG emissions. At the same time, we will be providing support for the decarbonizaion of society, with the aim of “contributing to the well-being and prosperous lifestyles of people around the world.”

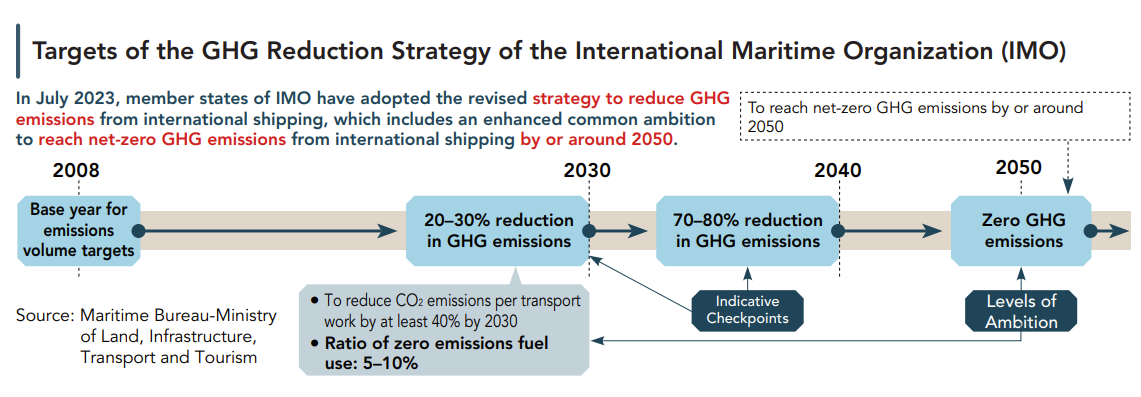

IMO targets

Our targets

The “K” LINE Group is taking steps to reduce GHG emissions in order to achieve low-carbon and carbon-free itself and throughout society and will invest a total of ¥330 billion by 2026 to establish competitive advantages while meeting needs for low-carbon and carbon-free operations.

Expanding introduction of LNG/LPG-fueled ships in the 2020s, investing in approximately 35 vessels by 2030

- Delivered “K” LINE’s first LNG-fueled car carrier, CENTURY HIGHWAY GREEN, in March 2021

- Plan to deliver “K” LINE’s first LNG-fueled cape-size bulk carrier in 2024

- We have decided to add thirteen LNG-fueled car carriers to our fleet deployed by 2026

Approximately 25% to 30% reduction in CO2 emissions compared with heavy-oil fueled vessels

- A very large gas carrier (VLGC), which is mainly fueled by LPG and capable of carrying LPG or ammonia, with a view to transporting ammonia was delivered in 2023

Approximately 20% reduction in CO2 emissions compared with heavy-oil fueled vessels

- 拡大

- Photograph provided by Kawasaki Heavy Industries,Ltd.

- Planning to have approximately 20 such vessels deployed by the mid 2030s

- Currently considering the introduction of zero-emission fuels such as ammonia/hydrogen as well as synthetic and other carbon-natural fuels

- Operated pilot voyage using B100 biofuel (marine biofuel made of 100% biodiesel) in May 2024

Zero CO2 emissions

- Seawing is a wind-powered propulsion system that uses the pulling force generated by flying a large kite attached to the bow of vessel for her propulsion

- In Januay 2024, we established OCEANICWING S.A.S. in France. This comany, which has taken over the business of Airseas following its spinoff from Airbus, is focused on further enhancing and accelarating the development and commercialization of Seawing technology.

- Seawing is a new thecnology that can be installed on any type of vessel, including retrofitting existing vessels, and we are considering deploying it on every kind of vessel.

- One of the features of Seawing is that it is a fully automatic system, with automation of everything from kite deployment to flight control and storage after use. The additional workload for crew members from kite oeration is minimal, as the system can be controlled with simple button operations from the bridge. Another notable feature is its versatility, as it can be used with any type of vessel, and can also be retorofitted onto existing vessels

- Looking ahead, it is expected that use of alternative fuels in place of heavy oil will expand. The prices of these fules are anticipated to be higher compared to heavy oil, but Seawing will demonstrate energy-saving effects even with these expensive fules. Seawing installation thus offers value from the twin perspectives of energy conservation and fuel cost reduction

Over 10% reduction in CO2 emiissions compared with existing vessels. (※The reduction rate varies depending on vessel speed, rout and season)

Anticipate to reduce CO2 emissons by 40-50% with the synergistic effect from installataion the system on LNG-fueld vessel

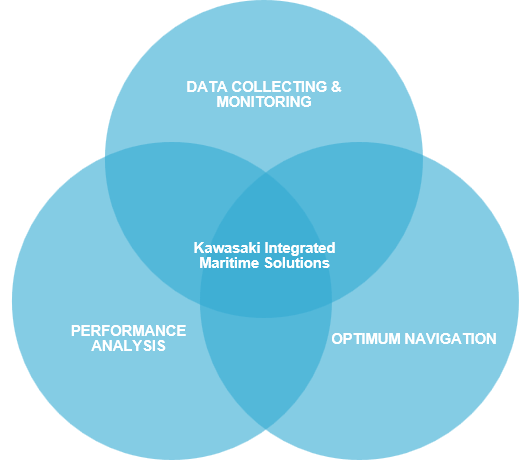

- Collects vessel operation data in real time, including fuel consumption, output power, and ship speed, and pursues the improved operational management of the vessel by using an optimal navigation system that calculates safe and fuel-efficient recommended routes

- Recently achieved visualization of performance degradation and impact of external disruption for each individual vessel using AI data analysis technology to further maintain and improve operational efficiency

Approximately 3% to 5% reduction in CO2 emissions through installation of Kawasaki Integrated Maritime Solutions

- World’s first CO2 capture plant on a vessel installed on coal carrier CORONA UTILITY as part of demonstration projects for Carbon Capture on the Ocean (CC-OCEAN), an offshore CO2 capture and storage plant, together with Mitsubishi Shipbuilding Co., Ltd., and Nippon Kaiji Kyokai (ClassNK)

- CC-OCEAN project wins Marine Engineering of the Year (Doko Memorial Award) 2021

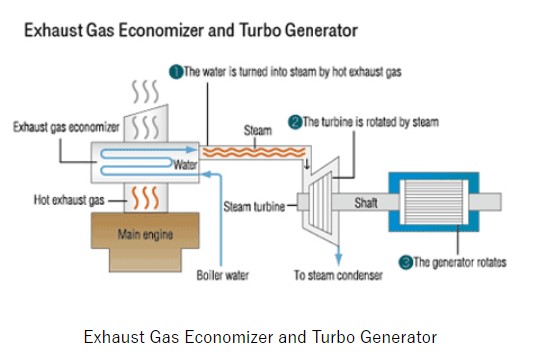

The fuel combusted in the engine to be converted into energy for maneuvering the ship is discharged into the atmosphere as exhaust gas. The thermal energy of this high-temperature gas is collected by the exhaust gas economizer to generate hot, high-pressure steam. If the steam is sent to turbo generators driven by the steam turbine and used to generate electricity for use onboard, it enables saving fuel necessary for electrical generation. Thus, this system that uses energy of the exhaust gas, which would normally be wasted, improves a ship’s energy efficiency, or the transport’s energy efficiency, enabling reduction of CO2 emissions.

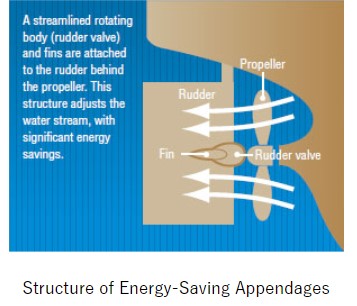

The rudder that maintains and changes a ship's direction is positioned at the back of the propeller and is continually subject to the water stream that the propeller generates. Then, if a spherical bulge and horizontal fins are attached to the rudder, it enables converting the propeller’s water stream into propulsion power. Since the propulsion power increases, that extra power permits lower fuel consumption and reduces CO2 emissions, while maintaining the service speed of the ship.

A ship is navigated to the destination port by following the course specified in the voyage plan. However, because a ship is subject to disturbances such as wind, waves and ocean current, she needs to be steered frequently to stay on course. An autopilot is a system that automatically steers the ship. It is used in areas where multiple ships do not converge, such as in mid-ocean. The latest type of autopilot is capable of learning the degree and duration of those disturbances and makes use of the data for the next steerage, thereby minimizing unnecessary operations. This reduces fuel consumption by about 1% compared with conventional units. We are striving to reduce the amount of CO2 emissions by continuing to install this state-of-the-art system in our ships.

- 拡大

- Steering stand with autopilot

Crew members’ onboard accommodations and the bridge for navigational watch are air-conditioned. However, ships are made of iron, which readily transfers heat, and subject to solar heat or outside temperature. This reduces the cooling/heating efficiency of air conditioners. We therefore use heat shield paint for outer plates of the accommodations and bridges to improve air-conditioning efficiency, and this reduces the electric power consumption needed for cooling and the amount of steam used for heating, which in turn means lower CO2 emissions.

- 拡大

- Heat shield paint is highly effective for a car carrier because the areas of accommodations and upper part ofthe brdge are large.

“K” LINE has introduced energy-saving hybrid transfer cranes at its own container terminals in Japan. These cranes, which are used at terminals to sort containers by destination, convert the energy generated when hoisted containers are set down in a pre-set location into electricity that is then reused as electric power. This cuts fuel consumption by about 40-50% compared to conventional cranes and greatly reduces noise.

Transfer crane: A self-propelled crane used for moving containers at a container terminal.

- 拡大

- Hybrid transfer crane

“BANGKOK COLD STORAGE SERVICE, LTD,” which operates in Bangkok, Thailand, installed solar panels on the roof of its 2nd warehouse in 2014. Output of the solar power system is up to 112.5kw, and total output in 2016 was 165mwh. This energy is equivalent to 13.9% of the annual electricity consumption at this warehouse and greatly contributes to energy saving. Further, “BANGKOK COLD STORAGE SERVICE, LTD” has been engaged in business operations in consideration of the environment since obtaining verification of ISO14001 in 2009.

- 拡大

- 2nd warehouse of "BANGKOK COLD STRAGE SERVICE"

- 拡大

- Solar panels installed on the roof of the 2nd warehouse

- Raised funds through Japan’s first climate transition loan (purpose specified finance) for the LNG-fueled car carrier, CENTURY HIGHWAY GREEN, in March 2021

- Raised approximately ¥110 billion through Japan’s first transition-linked loan (TLL) (purpose unspecified finance) in September 2021. Funds to be used to finance a range of environmental countermeasures aimed at decarbonization

- Full-scale internal launch of operation in April 2021. From fiscal 2022, this has been calculated with reference to an economic index that takes into account a future earnings contribution of ¥7,000 per ton of CO2

- Promote low-carbon transition and decarbonization projects by using them as an indicator for the evaluation of investment projects

We will promote initiatives, such as supporting the offshore wind power business, participating in and creating a fuel supply network for the hydrogen and ammonia transportation business, and participating in the CO2 transportation business, as a target for supporting the development of a low-carbon and carbon-free society set out in the “K” LINE Environmental Vision 2050, which aims to achieve net-zero GHG emissions by 2050.

-

Establishment of “K” Line Wind Service, Ltd., (KWS) in 2021 to participate in the offshore wind power generation vessl/carrier business

-

Signed a memorandum of understanding with Penta-Ocean construction Co, Ltd. in vessel management for the construcion and maintenance of offshore wind power facilities

-

Obtained ISO9001:2015 certification. Established a unique quality management system to evaluate and provide guidance on improvements to work support services for shipowners and ship management companies for offshore support vessles

-

Signed a joint reserch agreement with J-Power, TEPCO Holdings, Chubu Electric Power, and Albatross Technology for the Offshore Small-scale Demonstraion Research of Next-gereration(Floading Axis) Wind Turbines project

- 拡大

- Offshore support vessel

-

Received AiP certification from Nippon Kaiji Kentei Kyokai for a concept for a dedicated vessel for floating offshore wint turbines

-

As part of the Development of Low-Cost Construction Technology (for Installation of Floaring Wind Turbines) initiative of the 2024 Green Inovation Fund, we began promoting the basic design for dedicated floating offshore wind turbine vessels in cooperation with Japan Marine United and Japan Shipyards with funding from NEDO

-

The main purpose of these vessls is to efficiently perform work required for mooring, including mooring system transportaion, mooring system seabed installation and extension, and anchor grip force testing, and to meet a variety of needs for offshore wind farm process, from development to operation, including serveying, transportation, construction, and maintenance (Patent pending)

- 拡大

- Image of a dedicated vessel for floating offshore wind turbines

- Participation in CO2-free Hydrogen Energy Supply-chain Technology Research Association (HySTRA) with the aim of creating an international supply chain for the transportation to Japan of CO2-free hydrogen made from Australian brown coal. Implemented the world’s first verification tests for long-distance marine transportation in February 2022

- Considering re-entry into the ammonia transportation business

- Considering participation in the project to create a supply network for hydrogen and ammonia at all sites

- 拡大

- Photograph provided by Kawasaki Heavy Industries, Ltd.

In the CO₂ transportaion business, we entered into long-term contracts with Northern Lights for three liquefied CO₂ vessels for the word's first full-scale CCS project. We are also moving forward with construction of the NEDO demonstration vessel for liquegied CO₂ transportation and feasibility studies for CCS projects with key costomers and partners.

The finised Excool demonstration test ship for liquified CO₂ transportaion from NEDO

- The “K” LINE Group participates in the CCUS R&D and Demonstration Related Project / Large-scale CCUS Demonstration in Tomakomai / Demonstration Project on CO2 Transportaition, which NEDO opened to applicatins in fiscal 2021. Construction of the Excool demonstraion test ship - which will be used in the project - was completed, and the ship was put into operation

- Using our expertise in safe navigation and cargo handling, and experience in the demonstration testing of liquefied hydrogen transportation ships, we carried out a safety assessment of transportation and loading for the liquefied CO₂ demonstration test ship and have prepared an operation manual. Looking ahead, we will analyze the test data to contribute to the development of technology for the safe operation of ships carrying liquefied CO₂

NEDO's demonstration test are designed to systematize the know-how for low-temperature, low-pressure transportation

Enterd into a contract with Northern Lights for liquified CO₂ vessels

- In the field of liquefied CO₂ carriers involved in carbon dioxide capture and storage (CCS) - a concept for capturing and storing CO2 emitted during the use of hydrocarbons excavated from under the ground - “K” LINE has signed a long-term charter contract for the world's first fullscale commercial transport for CCS that is launching in Europe (the Northern Lights porject)

- Northern Lights has ordered a fleet of four vessels, three of them will be managed by The “K” LINE Group

Northern Lights is dedicated to systemaizing its know-how for medium-temperature, medium-pressure transportaion

Conducted studies for constructing CCS value chains with leading domestic and international companies

- Signed a basic agreement with PETRONAS for studying CCS commercialization in Malaysia

- Feasibility study toward the realization of the Setouchi-Shikoku CO2 Hub Concept

- Joint study with Tokyo Gas on liquified CO₂ vessel transportaion for CCS

- Signed a business consignment contract with Kansai Electric Power Company for designing liquefied CO₂ vessels, etc

- Participated in a research consortium on unloading liquefied CO₂ from onboard CO2 collection equpment

- Collaborate with Chubu Electric Power Co., Inc., on a tidal energy project in Canada (aim to begin operation in 2023)

- Looking into carbon credits, carbon offsets, etc.

- Participate in international think tank Global CCS Institute

- Participate in joint CCS study in Malaysia

Note: The offsetting of carbon emissions may be carried out through an internationally accepted method in the future