The world dry bulk market is characterized by growing demand for resource transportation in line with continuous economic growth in China, India, and other emerging nations. To meet such demand, which is diverse in nature, the “K” LINE Group has a wide variety of vessels and is building a fleet portfolio capable of providing a multitude of transportation services.

Fleet Composition

Fleet Size

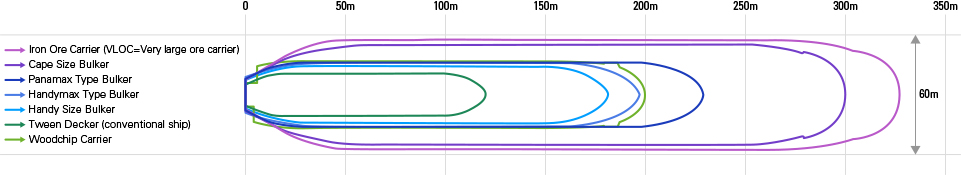

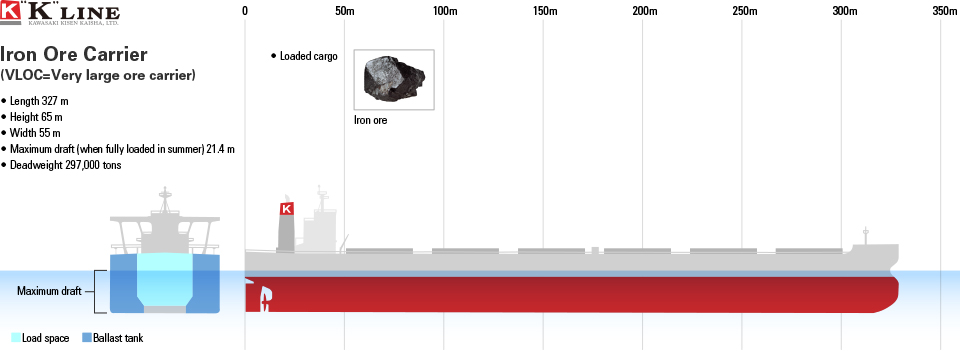

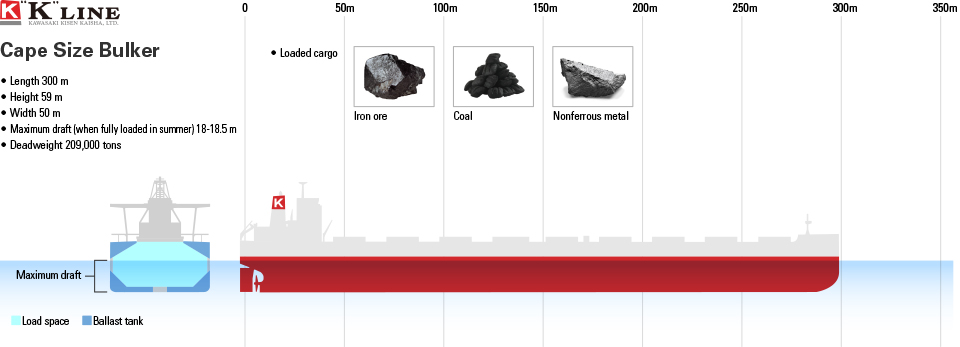

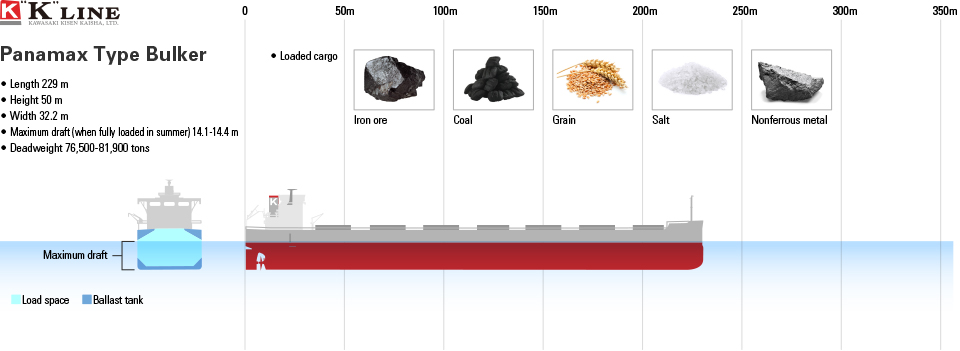

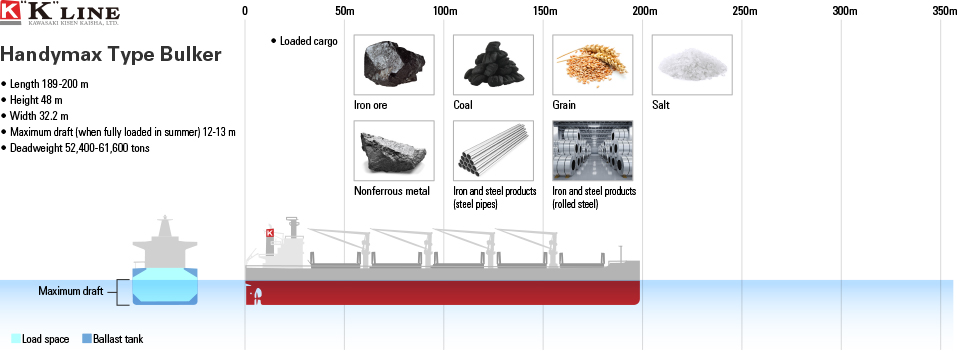

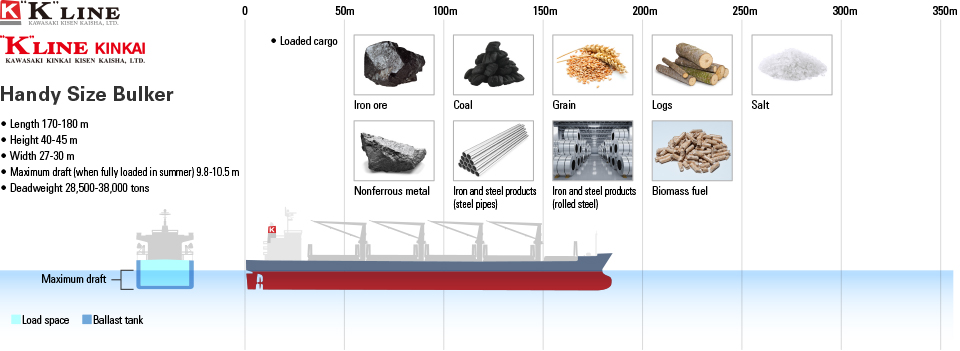

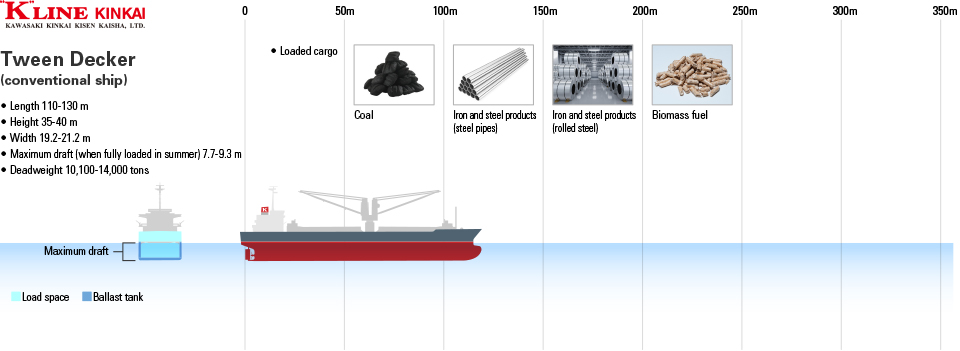

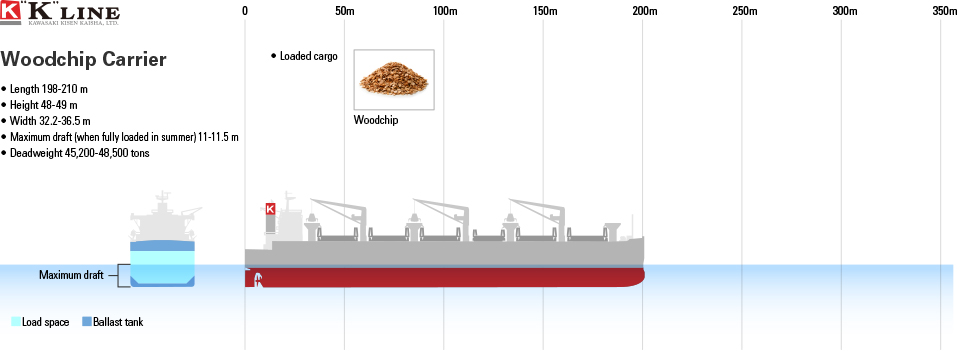

Following figures of length, height, width and maximum draft are approximate.

This is the largest type of vessel for carrying dry bulk.

It is designed for the efficient transportation specifically of iron ore, which is heavy.

Being such a large vessel, it requires both large-scale ports for entry and large cargo-handling facilities.

In addition to iron ore, this vessel is used for bulk transportation of coal and other industrial raw materials as well as fuel consumed in large quantities. It is a symbol of the modern dry bulk market.

It is a large vessel, though somewhat smaller than dedicated iron ore carriers, so ports and cargo handling facilities that can accommodate it are limited in number.

This is one of the largest general-purpose vessels that can pass through the Panama Canal and berth in numerous world ports. Without its own loading equipment, it can only function at ports that have such equipment.

With seven cargo holds, the vessel can carry varying types of cargo in addition to coal and iron ore.

This is the second-largest general-purpose vessel after Panamax that can pass through the Panama Canal and berth in numerous world ports. It has its own cargo handling equipment (crane), so can function in various ports.

With five cargo holds, some vessels have been configured to easily carry steel materials and other products in addition to bulk cargo.

This is a small-size vessel among “K” LINE’s dry bulk carriers, however, due to its small size and very user-friendly hull, it can enter more ports than larger vessels and meet the demand for the transportation of various cargoes.

Its box-shape cargo hold enables good loading and unloading efficiency and makes it easier to keep cargo secure during transportation. Some vessels have been configured to allow cargo to be loaded on the deck.

Similar to Handymax, it is equipped with a strong crane and can function at ports without loading facilities.

Click here for more details about KAWASAKI KINKAI KISEN KAISHA, LTD.

With a layered configuration called “double-layer deck ship,” this vessel can be loaded with separate upper and lower cargoes.

It is difficult to load certain products, such as steel and timber materials, from bottom to top inside a bulk carrier, so the upper part remains as empty space. The great feature of this vessel is that it efficiently utilizes such space and appears small, allowing numerous port-berthing options.

The two adjacently aligned cranes can be paired to load up to approx. 70 metric tons, allowing the vessel to load heavy objects according to project requirements.

Unlike other dry bulk carriers, this is a dedicated ship designed for transporting woodchips.

It is designed to allow large volumes to be loaded into the hold for the efficient transportation of light, bulky cargo.

In addition, it has a crane, hopper, and conveyor belt for loading and unloading woodchips on the deck of the ship.

PICK UP!

The Corona-series of thermal coal carriers was developed by “K” Line on its own, and are being highly estimated by cargo owners. The high-profile feature of wider hull requiring a shallower draft is designed in consideration of berth conditions at power plants. The Corona-series has been gradually developing into a standard for thermal coal shipping business in Japan.