Safety in navigation and cargo operations is an immutable mission in operating a shipping business. The “K” LINE Group includes “providing safe and optimized services” in its corporate principle and vision and has established the following three policy pillars in order to fulfill its social responsibility through safety in navigation and cargo operations:

(1) Enhancing management structure for ensuring safety in navigation

(2) Strengthening the ship management system

(3) Reinforcing the securing and training of maritime officers

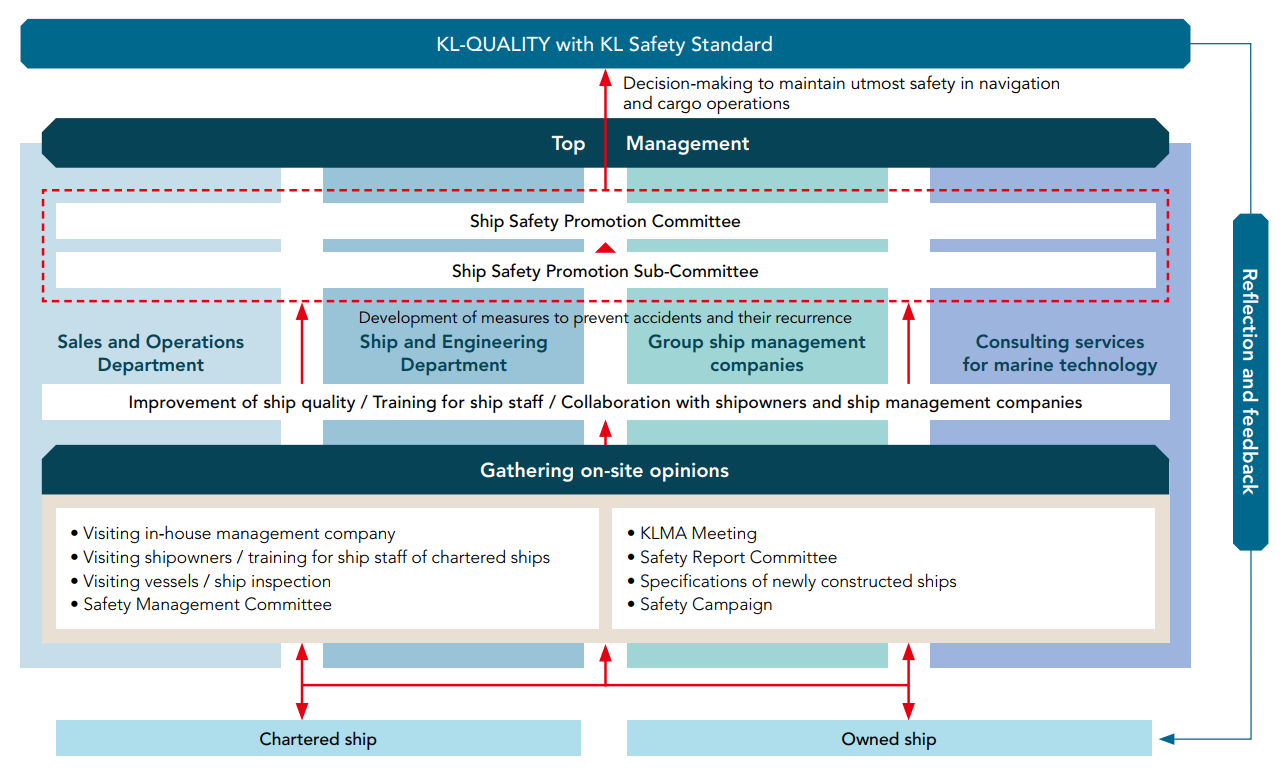

The Ship Safety Promotion Committee, chaired by Representative Exective Officer, President & CEO, is the top decision-making body covering safety. It determines accident prevention and safety measures for all ships operated by the Company—including owned, chartered, and entrusted vessels—and handles everything from basic policy formulation to implementation of measures under the system shown below.

The “K” LINE Group establish a global monitoring network with three bases that comprehensively spans the world, allowing the Group to maintain 24-hour safety support for its fleet sailing anywhere in the world as well as to respond to emergencies. The bases in Asia, Europe, and the Americas materialize 24/7 response and support the safe navigation of ships with referring weather and voyage plans through the sophisticated monitoring system. The network also assists the fleet in emergencies and facilitates coordination between the head office and ship management companies.

We believe that the most crucial factor for safety in navigation is human capabilities. To achieve safety in navigation, it is essential to secure and develop competent human resources, strengthen the marine technical support system that ensures close customer relations, and establish and operate the global safety management network. Furthermore, to achieve high levels of safety and quality in transportation, it is necessary to promote the digitization of experience through advanced digital technologies in order to complement human capabilities. Drawing on both human capabilities and advanced digital technologies, we will strengthen the global monitoring system and provide safe and optimized services, with priority given to our customers.

In recent years, data has been increasingly used to improve safety and quality, and internet connections are used to share vessel navigation data from ship to shore. It has also become necessary to upgrade ICT equipment and networks on ships because of improvements in satellite data transmission capacity. With a view to increased potential cyber risks as ship-to-shore internet connectivity evolves, ship management companies that belong to the “K” LINE Group have obtained Cybersecurity Management System (CSMS) certifications from Nippon Kaiji Kyokai (ClassNK) since 2020. We continue efforts to enhance our ability to respond to cyber risks on ships.

Through in-house ship management companies that share our corporate principle, we provide higher-quality, safer, and more secure services by making full use of our expertise with regard to different vessel types.

|

Ship management company |

Vessel type |

|

K MARINE SHIP MANAGEMENT PTE. LTD. |

Oil tanker, LPG carrier, LNG carrier |

|

“K” Line Ship Management (Singapore) Pte. Ltd. |

Containership |

|

“K” LINE ENERGY SHIPPING (UK) LIMITED |

LNG carrier, Liquefied CO2 carrier |

|

“K” Line RoRo Bulk Ship Management Co., Ltd. |

Car carrier, Dry Bulk Carrier |

Prior to embarkation, the head office and in-house management companies conduct a pre-embarkation briefing for senior officers (captain, chief engineer, chief officer, and first engineer) to share the Company’s policies and the latest information on safe operations to ensure that our safety management system permeates all the way to the front lines.

When our ships call at a port, ship operator, marine safety department, safety superintendents, superintendents in charge of ship management companies, and other personnel visit the ship to conduct activities for ensuring safe navigation and cargo operations, including discussions with crew members and inspection of the ship’s hull and onboard equipment.

During the annual Safety Campaign period, we focus various activities, including ship visits by Company’s top management to have discussions with ship captains and crews, to provide an opportunity to further raise awareness about both safety in navigation and environmental protection across the entire “K” LINE Group, both at sea and on shore.

Reports of near misses such as unsafe behavior on vessels are carefully analyzed by experienced maritime officers onshore, and the results are shared in the fleet. By embedding a no-blame culture, where who made the near miss is never blamed, we share thousands of reports annually, which helps safety awareness to take root on the front lines.

AIMS is an accident information management system aimed at processing accident cases appropriately and swiftly, analyzing accident trends, and formulating effective prevention measures.

We are taking various actions to eliminate accidents, using this system to analyze accident details and trends and to explore in depth the root causes of accidents. By creating a database of accident information, moreover, we are able to share information with our worldwide network in a timely manner and implementing optimal safety measures.

We regularly conduct exercises based on scenarios of major accidents involving ships under our operation to ensure we can respond quickly and properly in the event of an emergency. This exercise involves practical training and covers everything from assembling an initial emergency response team to establishing an accident response headquarters and internal information-sharing systems, as well as setting up systems for communicating with overseas parties and verifying media responses.

As part of strengthening our safety management structure, we monitor the vessels under operation, including chartered vessels.

We work to prevent navigation accidents by monitoring route deviations and any severe weather anticipated for each vessel on a single platform, then sharing this information between ship and shore.

We have established 24/7 monitoring and safety navigation support system through monitoring in three bases worldwide.

“K” Line-Drive to No Accident (K-DNA) is our unique policy for safety equipment installation that reflects accumulated knowledge and lessons learned from past accidents. It consists of equipment installation standards for navigation, engine, safety, piracy countermeasures, etc. By gathering expertise from all segments, we are continuously developing and strengthening hardware safety in our fleets. Namely, this is the very DNA of “K” LINE’s history of safety.

Ship inspection supervisors regularly visit vessels to implement onsite inspections based on our unique quality policy called KL-QUALITY, which is applied to all vessels under our operation (including chartered vessels), as a guideline.

Additionally, we hold a Safety Management Committee meeting once a year to share information and exchange opinions with long-term chartered ship owners and ship management companies. Outstanding ship owners will be recognized for their performance in the Commitee meeting.

The “K” LINE Group has obtained class notation* for our car carriers indicating that safety measures are in place for transporting electric vehicles by sea. The “K” LINE Group has been working to strengthen its initiatives for safe automobile transport, and obtaining this notation serves to recognize these efforts.

* Class notation refers to additional character symbols given by classification society to vessels and systems that meet requirements.

By developing a shared system for automatic creation of plans for loading steel, iron ore, and coal, “K” LINE aims to maximize loading volume, optimize cargo loading, and introduce laborsaving measures for onboard operations through fulfillment of the various needs and different conditions of customers. Currently, we create loading plans based on knowledge of the officers and marine engineers on board; we have successfully completed verification tests for the automatic creation of plans through algorithms utilizing advanced mathematical optimization technologies to achieve the same loading volume as an experienced marine engineer in a short time. By utilizing DX, we are promoting the creation of an environment that reduces the burden on officers on board and enables us to focus on safety in navigation, which is our most important mission.

|

Year |

2020 |

2021 |

2022 |

2023 |

2024 |

|

Cases |

0 |

0 |

0 |

0 |

0 |

* The scope of this data is “K” LINE’s scope of consolidation, which corresponds to 100% of sales.

Port State Control (PSC) is a safety inspection of foreign ships conducted by port states to verify that the condition of the ship complies with the requirements of international regulations.

The number of deficiencies with “K” LINE Group vessels per PSCs is well below the average number of deficiencies in the main regions.

* The scope of this data is "K" LINE's scope of consolidation, which corresponds to 100% sales.

* TOKYO MOU:PSC organization in Asia-Pacific region

* PARIS MOU:PSC organization in European and North Atlantic region